Ercolina Tube & Pipe Bending Machines

Ercolina offers a full line of high-quality tube, pipe, and profile bending machines engineered for consistency, efficiency, and performance. Whether you’re working with round tube, pipe, square tubing, or solids, Ercolina benders provide durable, repeatable results across a wide range of applications. Their innovative no-hydraulic designs reduce maintenance needs and offer precision control through intuitive touchscreen systems and fast-change tooling.

Super Bender® Series

Super Bender® Plus: 2″ mild steel capacity, 1-1/2″ Sch. 40 pipe. Features one-touch programmable bending, springback compensation, and compact storage-friendly design. Ideal for tube, pipe, squares, and solid profiles.

Super Bender® SB48: Touchscreen control, springback compensation, and digital display. Compatible with the A40-P positioning table and offers portable mobility with base wheels.

Top Bender® Series

Top Bender® Plus: 2-1/2″ tube, 2″ pipe capacity. Real-time color control display with programmable angle and springback. Quick-change tooling and swing-away vise simplify operation.

TB60: Adds touchscreen controls and advanced springback monitoring for up to 2-1/2″ tube. Designed for consistent, accurate bends with programmable options and A40-P compatibility.

TB100, TB130, TB180: Heavy-duty models handling up to 6″ pipe or 5″ tube with tight CLR capability and remote or touchscreen controls. No hydraulic components. Designed for industrial bending needs.

Medi Benders

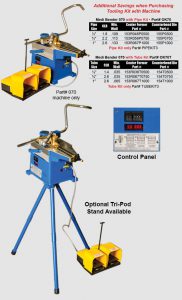

070 Medi Bender: Compact, job-site portable with 1-1/4″ tube capacity. Remote foot pedal, rotary dial control, and quick-change tooling system.

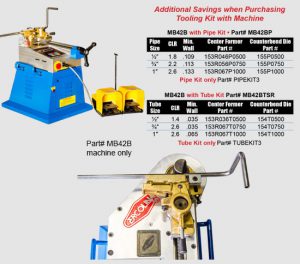

MB42B Benchtop & MB42: Ideal for conduit, copper, hydraulic tube, and small profile work. Touchscreen programming, foot pedal operation, and portable bench designs with quick-change tooling.

Mandrel Bending Machines

030 Mandrel Bender: Up to 2.5″ mild steel tube. Offers programmable bend angle, mandrel retraction, clamp/pressure die control, and optional software for setup guidance.

TM76 Top Mandrel Bender: Semi-automatic with touchscreen interface and USB storage. Up to 3″ mild steel. Features programmable mandrel position and springback compensation.

EB65CNC3V1 & EB76CNC6V5: Advanced 3-axis CNC systems with touchscreen controls. Up to 3″ tube capacity with programmable sequences, carriage motion, and precision tooling adjustments.

GB100CNC, GB130CNC, GB200CNC: Industrial-grade Giga Benders with up to 6½” tube capacity. Hydraulic multi-axis control, springback compensation, touchscreen diagnostics, and USB program backup.

All capacities based on A53 grade A 48,000 psi tensile materials. Heavier walls or higher tensile materials may reduce machine capacity. Consult supplier for exact specifications.

Looking for the right Ercolina Bending Machine for your shop?

Contact our team or request a quote today to learn more.

Super Bender Plus

Top Bender Plus

TB100 Top Bender

TB180 Top Bender

Medi Bender 070

Medi Bender MB42B

030 Mandrel Bender

TM76 Top Mandrel Bender

Erco Bender 65CNC3V1

GB200CNC Giga Bender

Need help selecting the right Roper Whitney brake?

Contact our team or request a quote today.