Davi

Davi offers a wide range of high-performance plate and angle rolls designed for precision and efficiency. With a focus on heavy-duty applications, Davi’s rolling machines provide advanced features and robust construction to ensure consistent performance, reliability, and ease of operation. Explore the range of three and four-roll machines for bending, crimping, and shaping metal plates and sections.

Plate Roll

Three Roll

MAV – VARIABLE GEOMETRY PRESS-ROLLRANGE: For plate thickness from 80-100mm (3-4 inches) and above, the MAV is the best solution for very heavy-duty applications in materials with medium to high yields and ultimate tensile strength.

PRESS-ROLL DESIGN: The MAV’s top roll moves in an up-and-down direction, while the two side rolls move in and out, changing the bed width, similar to the bed of a press brake. This design makes it easy to operate.

VARIABLE GEOMETRY: The MAV’s variable geometry allows the operator to move each side roll independently, optimizing leverage for any application. This allows the MAV to have the shortest flat end possible, minimizing waste.

MCO – THREE ROLL DOUBLE PINCHRANGE: The MCO is a fixed top-roll design, with two side rolls that swing up for pre-bending and rolling. It is a cost-effective option for rolling plates from 15-20 mm (5/8 – 3/4 inch) thickness, up to 80-100 mm (3-4 inches), and more.

NO REMOVAL OF PLATE: The MCO allows both ends of the plate to be pre-bent without removing the material, a feature not available on single pinch or asymmetric designed machines.

POWERED ROLLS: The MCO features three independently powered rolls, ensuring excellent plate feeding without slippage, even with narrow, large diameter cylinders.

Four Roll

MCA – FOUR ROLLRANGE: The MCA is designed for rolling light gauge plates up to 10-15 mm (1/2 inch) thick. It is a fast, accurate, and easy-to-operate plate roll, ideal for light to medium applications.

ONE PHASE CYCLE: Unlike a three-roll machine, the MCA allows for simultaneous pre-bending and rolling of the plate in a single motion, reducing cycle times.

CNC CONTROLLED: The MCA features advanced CNC controls that reduce the need for experienced operators and improve efficiency.

MCB – FOUR ROLLRANGE: The MCB is ideal for high-production, mid-heavy applications, rolling plates from 15-20 mm (5/8 – 3/4 inch) up to 80-100 mm (3 – 4 inches) thick.

ONE PHASE CYCLE: Similar to the MCA, the MCB can roll plates with pre-bending in one motion, ensuring a smooth, continuous process.

CNC CONTROLLED: The MCB is equipped with advanced CNC controls for maximum productivity and precision.

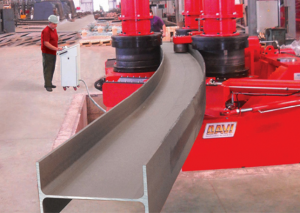

Angle Roll MCPThe MCP is designed for demanding applications where very large or extra-large parts need to be bent with strict tolerances. It features the heaviest and strongest machine structure in the industry, offering excellent performance for bending non-standard profiles and heavy-duty beams, pipes, and spirals.

Machine Gallery

MAV

MCO

MCA

MCB

Angle Roll MCP

Looking for the right Davi Rolling Machines for your shop?

Contact our team or request a quote today to learn more.