Ercolina

Angle Rolls

Ercolina offers high-performance angle rolls with precision and durability. These models are ideal for bending various materials, providing reliable operation for a range of applications. Below are the key features of some of the top models:

CE35 ANGLE ROLL

- 40mm roll shaft diameter

- Maximum pipe capacity 1-1/2″ Sch. 40

- Maximum angle capacity to 1-1/2″ x 1-1/2″ x 1/4″

- Forged roll shafts for minimal deflection

- Heavy-duty structure for high section modulus ratings

- Inline direct drive roll shaft system

- Optional Anti-twist correction system for angle iron “Leg In” applications

CE40 ANGLE ROLL

- 40mm roll shaft diameter

- Maximum pipe capacity 2″ Sch. 40

- Maximum angle capacity 2″ x 2″ x 1/4″

- Programmable touchpad controls with digital center roll position display (on hydraulic model)

- Hydraulic model includes memory storage with 8 individual programs

- Threaded roll shafts with micrometric flange adjustment

CE50 ANGLE ROLL

- 50mm roll shaft diameter

- Maximum pipe capacity 2-1/2″ Sch. 40

- Maximum angle capacity 2-1/2″ x 2-1/2″ x 1/4″

- Programmable touchpad controls with digital center roll positioning display

- Threaded roll shafts with micrometric flange adjustment

- Hydraulic machine with memory storage and unlimited passes

CE60H3 ANGLE ROLL

- 50mm roll shaft diameter

- Maximum pipe capacity 3″ Sch. 10

- Maximum angle capacity 2-1/2″ x 2-1/2″ x 3/8″

- Uses same tooling as CE50

- Hydraulic machine with memory storage and 8 individual programs

- Inline direct drive roll shaft system 3-roll driven

CE70H3-RLI ANGLE ROLL W/HYDRAULIC 3 AXIS TWIST

- 70mm roll shaft diameter

- Maximum pipe capacity 3″ Sch. 40

- Maximum angle capacity 3″ x 3″ x 3/8″

- Three-axis hydraulic twist system for angle iron “Leg-in” applications

- Programmable touchpad controls with digital center roll positioning

- Memory storage with 8 individual programs and unlimited passes

- Inline direct drive roll shaft system with motor and brake on each shaft

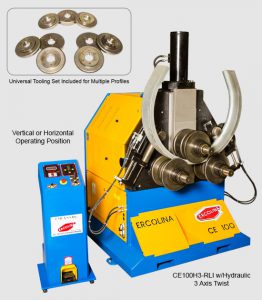

CE100 ANGLE ROLL

- 100mm roll shaft diameter

- Maximum pipe capacity 4″ Sch. 40

- Maximum angle capacity 4″ x 4″ x 1/2″

- Three-axis hydraulic twist system for angle iron “Leg-in” applications

- Programmable touchpad controls with digital center roll positioning display

- Inline direct drive roll shaft system with motor and brake on each shaft

Machine Gallery

CE35

CE40

CE50

CE70

CE100

Looking for the right Ercolina Angle Rolls for your shop?

Contact our team or request a quote today to learn more.