Vicon Machinery

Vicon Machinery offers comprehensive cutting solutions from quoting and CAD to cutting and support. Our systems provide unmatched reliability, efficiency, and flexibility for a wide range of industrial applications, including HVAC cutting, fabrication, and precision plasma cutting.

All machines come with a one-year warranty, onsite setup and training, and lifetime technical support.

HVAC Cutting Solutions

Vicon’s HVAC cutting machines are engineered for high-speed, precise plasma cutting of HVAC ductwork and sheet metal, offering a competitive edge by reducing material waste and operating costs.

HVAC 510 Sheet Cutting System

The Vicon HVAC 510 is a rugged and flexible plasma cutting system ideal for HVAC duct fittings. It delivers fast, accurate cuts while minimizing material waste, offering great reliability and productivity.

HVAC 520 Dual Table Cutting System

The HVAC 520 doubles productivity with dual tables, allowing one end to unload while the other continues cutting, streamlining operations and reducing turnaround time.

HVAC 520-DL Duct Liner Cutting System

The HVAC 520-DL cuts both metal and duct liner on separate beds, reducing setup time. With automated bar code scanning and true-shape nesting, material waste is minimized, and sorting becomes seamless.

Vi-Stream Waterjet Liner Cutting System

The Vi-Stream system offers efficient liner cutting using waterjet technology, maximizing uptime and minimizing maintenance with its durable and easy-to-clean design.

Plasma Feeder

The Vicon Plasma Feeder system automatically feeds material to plasma cutters, reducing labor and scrap, and improving the overall material handling process.

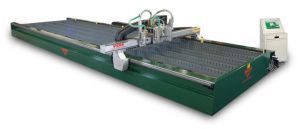

Fabricator Series Plasma Cutting Tables

The Vicon Fabricator series provides heavy-duty, high-performance plasma cutting machines designed for versatility in fabrication and job shop environments.

Fabricator-HD

The Fabricator-HD is ideal for job shops, offering exceptional cutting accuracy and minimal waste, with dual rack and pinion drives for precision.

Fabricator-SS

The Fabricator-SS is designed for applications requiring high precision and clean edge cuts. It offers advanced features, including solid-state controls and automatic exhaust signals for energy savings.

Precision Plasma Cutting Systems

Elite Precision Plasma Cutting Table

The Vicon Elite system delivers high precision, offering flexible options such as plasma, oxy torches, and drill heads for high-quality, accurate parts.

Monarch Heavy-Duty Precision Plasma Cutting Table

The Vicon Monarch system offers rigid construction and precision cutting capabilities for heavy-duty applications such as sheet metal, plate, and structural steel, ensuring durable performance for years.

Machine Gallery

HVAC 510

HVAC 520

HVAC 520-DL

Fabricator-HD

Fabricator-SS

Elite

Monarch

Looking for the right Vicon machine for your shop?

Contact our team or request a quote today to learn more.